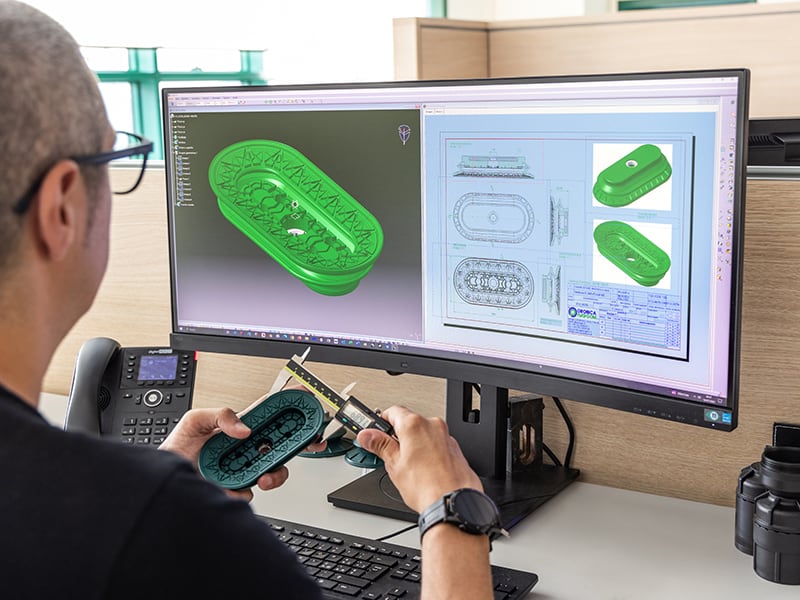

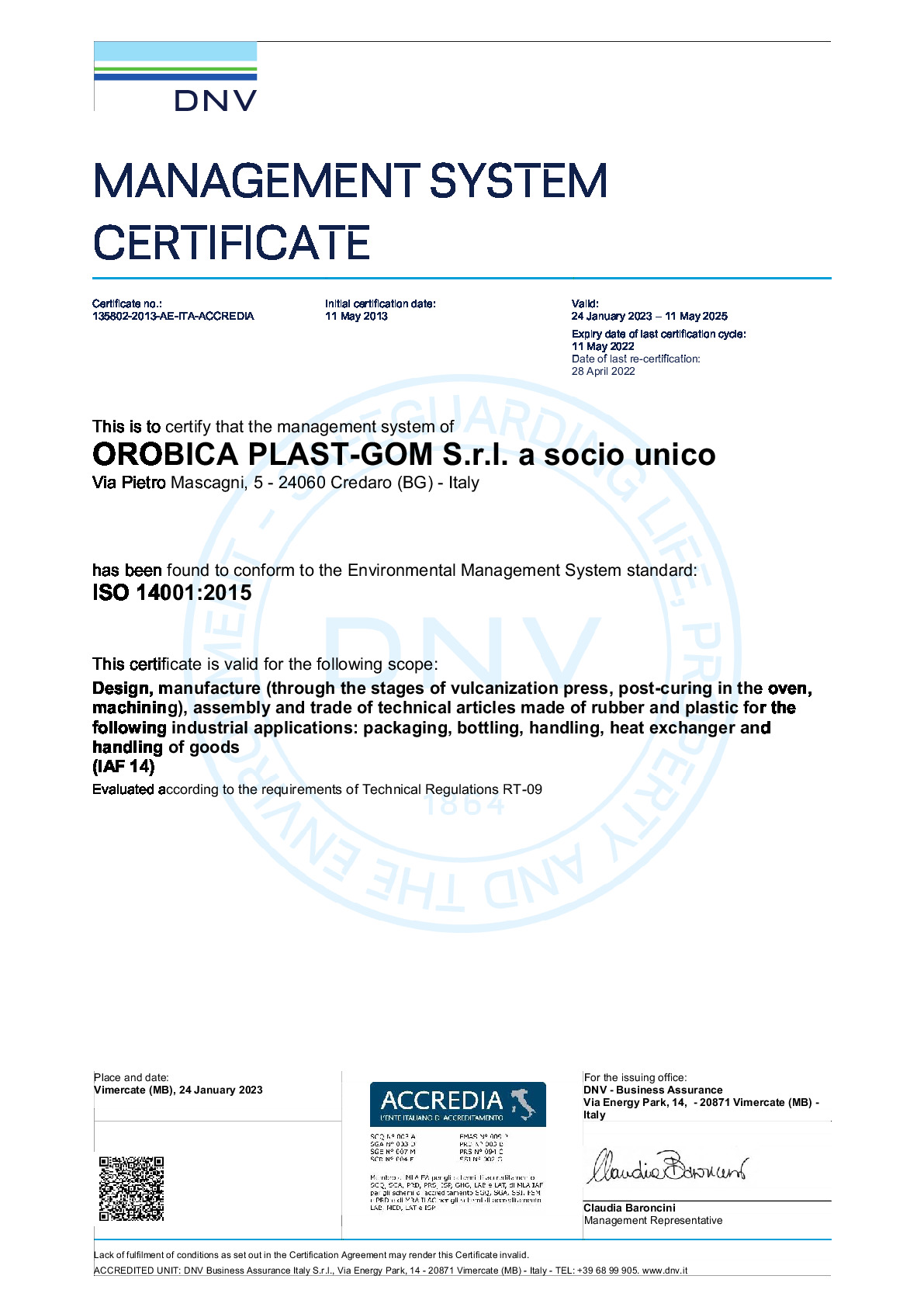

Any Orobica Plast-Gom product, whether it is a suction cup, gasket, membrane, or a custom-made item, is carefully monitored at every stage of its production, from design to raw material selection, through processing and pre-market testing. Not surprisingly, an increasingly demanding clientele relies on Orobica Plast-Gom’s components and its quality system certified by UNI EN ISO 9001, UNI EN ISO 14001.

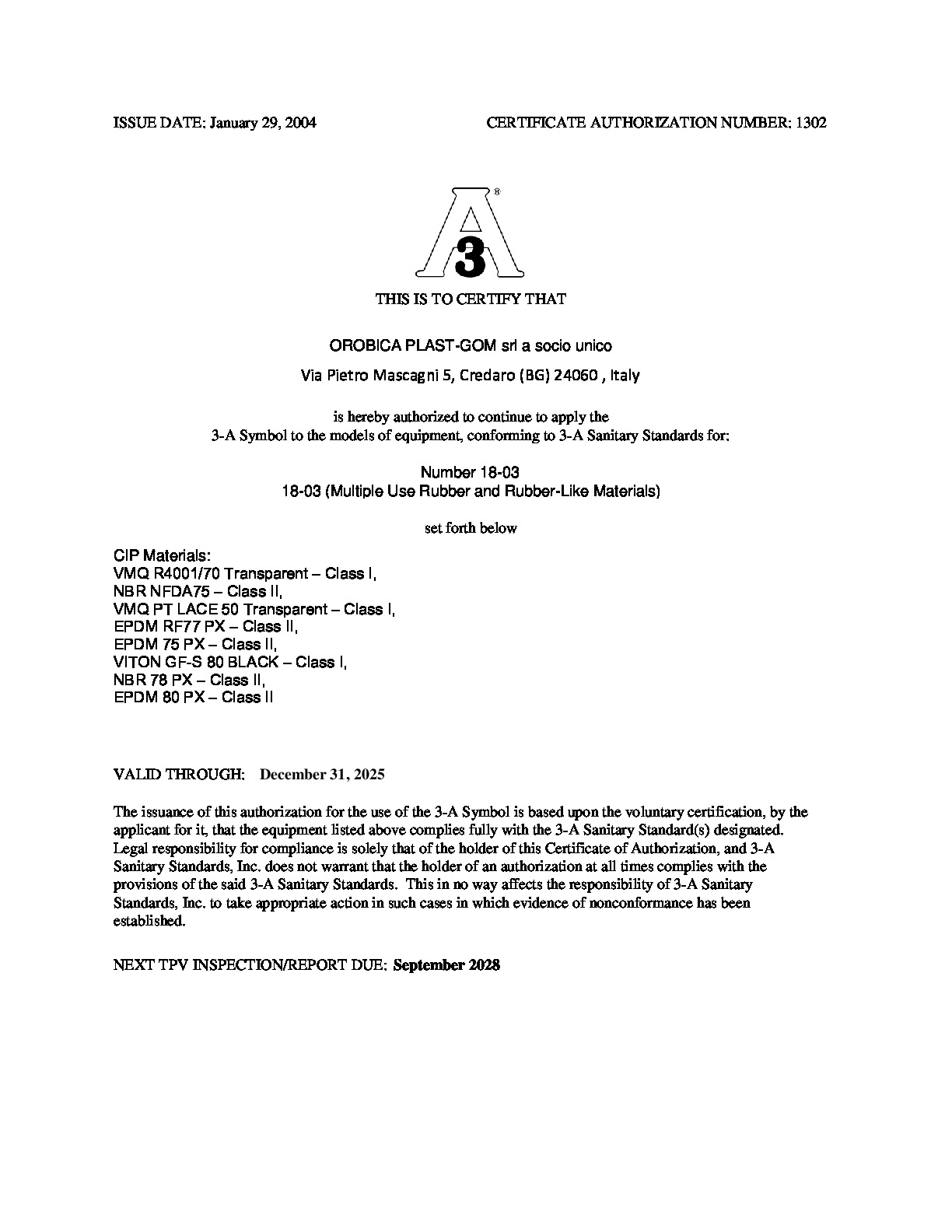

For products destined for the food market, we comply with the following certifications: FDA, KTW, BFR, EN 1935/2004, 3-A Sanitary Standard, French Arrete.

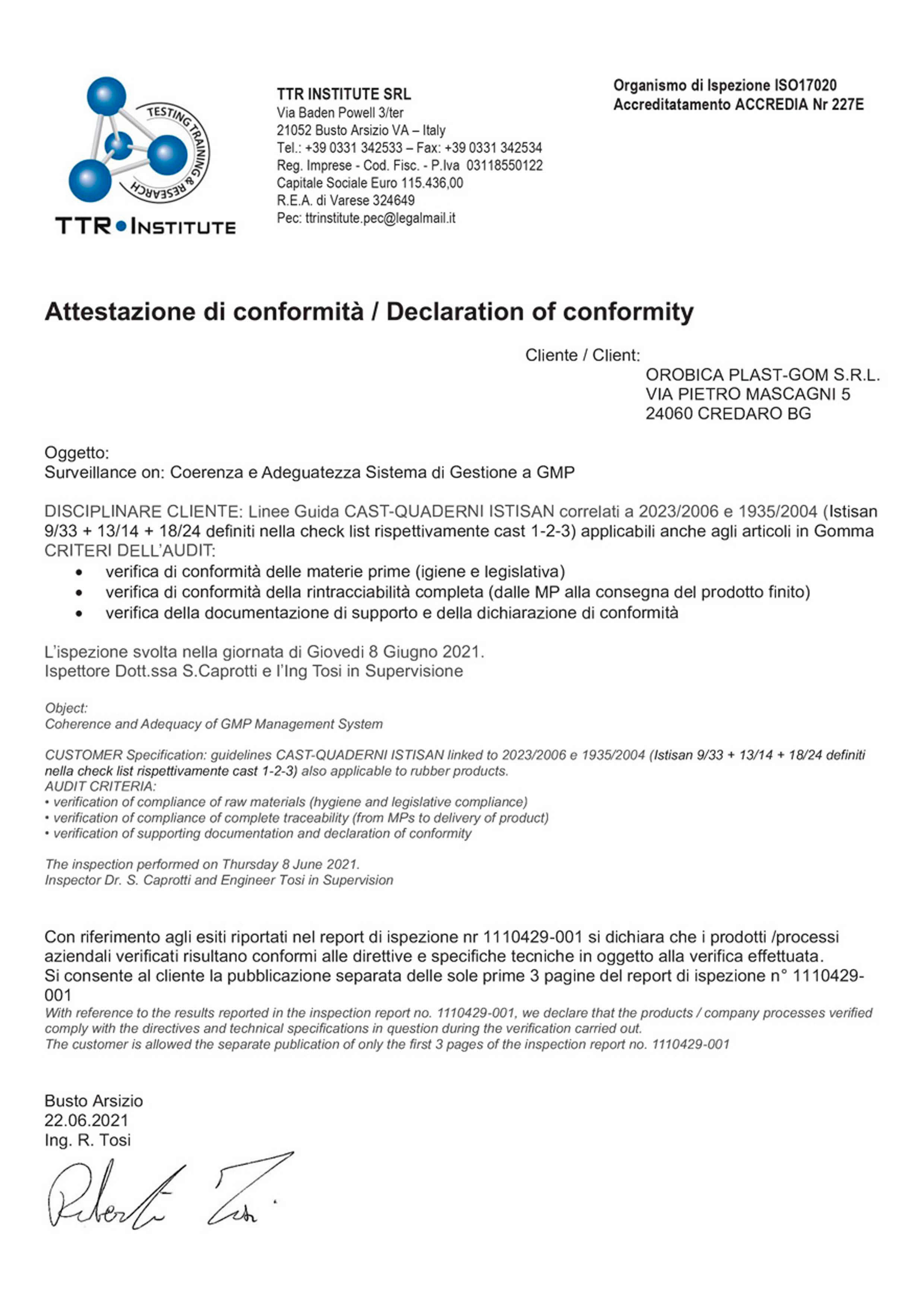

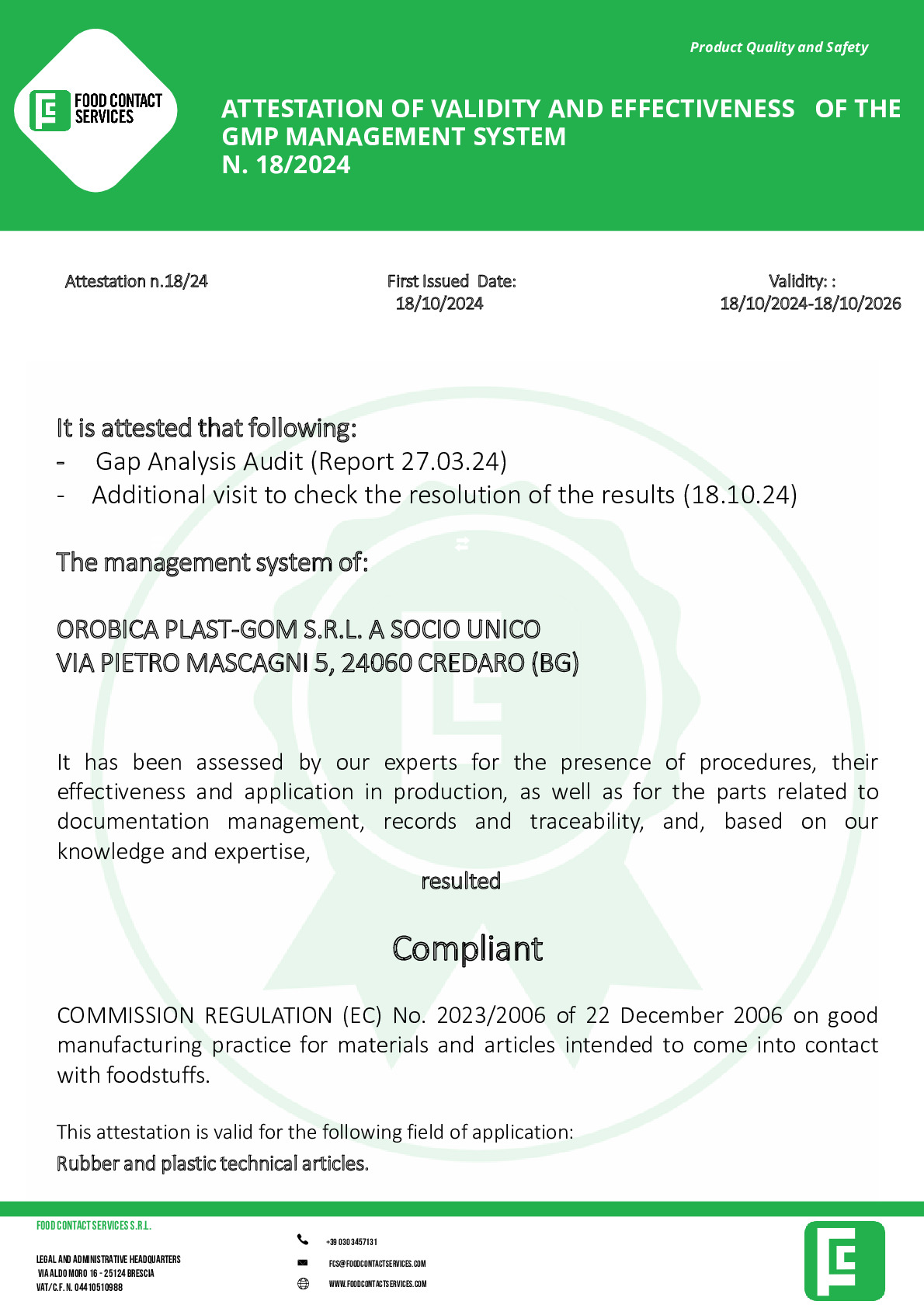

Our production system is also certified according to EU2023/2006-GMP Good manufacturing practice for materials and articles intended to come into contatc with foodstuffs

For products destined for the pharmaceutical market: USP class VI. For gaskets intended for nuclear energy production: EDF.

These recognitions confirm the meticulousness and consistency of precise and accurate production processes, as well as the professionalism of serious and qualified personnel.

A twenty-year experience, continuous research, and careful selection of suppliers allow us to maintain a high-quality standard, which is evident from the choice of raw materials.

But also, internal and external laboratory tests, recognized worldwide, and active cooperation with clients and suppliers, create unique collaborative synergies, in the common interest of always offering the best in production technologies and quality guarantees.

EU2023/2006-GMP Good manufacturing practice for materials and articles intended to come into contatc with foodstuffs

of all-Italian quality

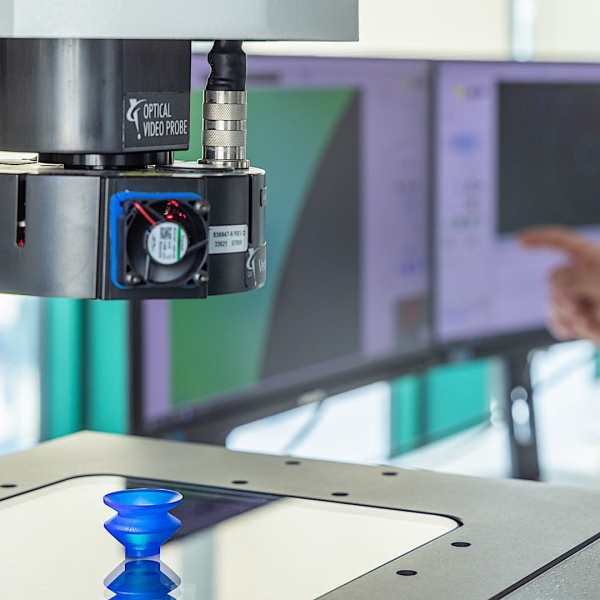

At the same time, Orobica Plast-Gom begins designing and producing gaskets for plate heat exchangers, a sector where factors such as material quality, accuracy, and precision in various stages of processing play a key role in providing competitive and complete service to customers.

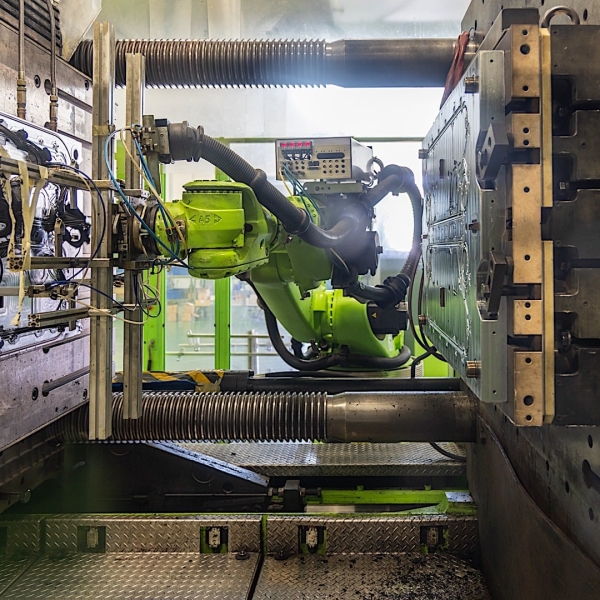

The company settled in the new industrial hub, an efficient multifunctional structure spread over an area of over 10,000 sqm.

Orobica Plast-Gom's activities are divided into several contiguous sites, housing management, research and development, production, quality control, and storage.

RM Service is established.

Company specialized in the production and supply of maintenance, overhaul and spare parts services for plate heat exchangers.

Acquisition of Gamavuoto.

A leading company in the supply of vacuum products for the industry.

Flexilis is established.

Specialists in the production of technical items in elastomers, thermoplastic elastomers, and thermoplastics, manufactured based on samples or customer designs, with no shape limitations.

Gamavuoto Germany is established.

The company's global vision is becoming increasingly rooted in the European market.

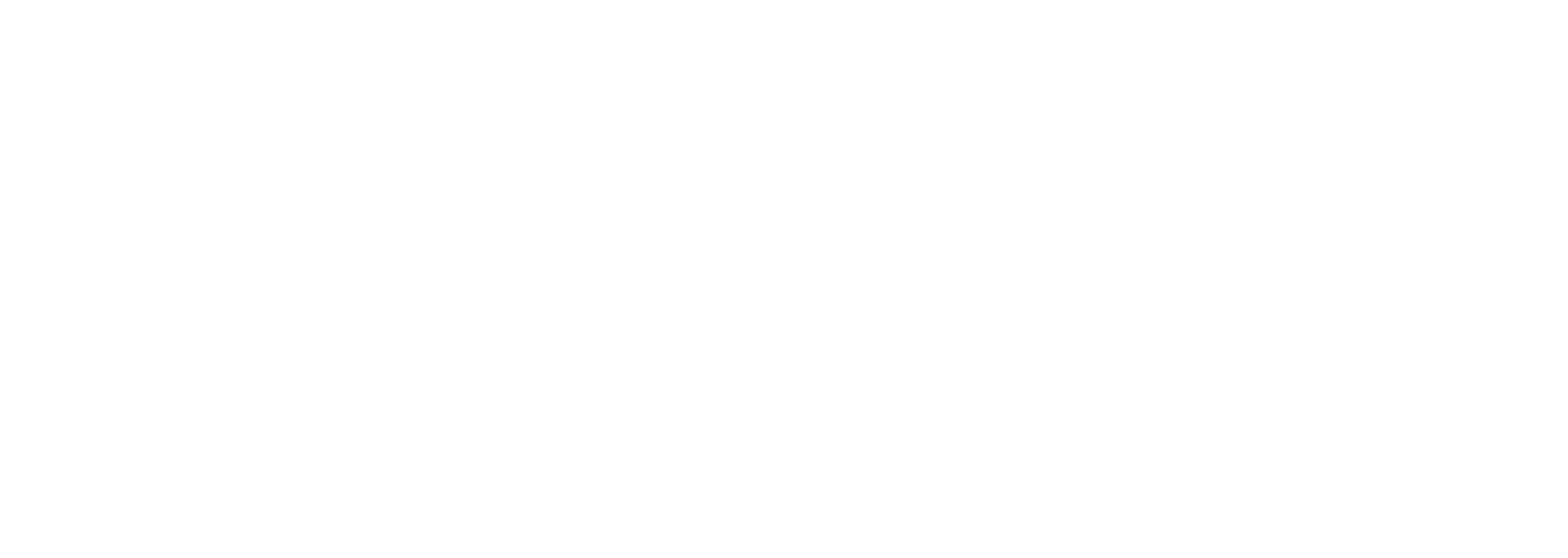

Acquisition of Regro.

An Italian company specialized in the design and manufacturing of injection and compression molds for thermoplastic materials.